Welding Automation

This is the normal gantry having three directional movements.

- 1staxis Horizontal left and right movements Stroke=7000mm,

- 2ndaxis Vertical up and down movements Stroke=1200mm,

- 3rdaxis Horizontal front and back movementsStroke=800mm,

All the three axis are controlled by PLC or CNC and can synchronize together.

Application

- Thermal spray,

- Painting,

- Pick and place application.

| SPEC\MODEL | GR-250 | GR-500 | GR-1000 | GR-2000 | GR-3000 | GR-4000 |

| PAY-LOAD (Kg) | 250 | 500 | 1000 | 2000 | 3000 | 4000 |

| CARRIAGE PLATE | CUSTOMISED TO CUSTOMER | |||||

| Repeatability | +/- 0.02mm | |||||

| Lubrication | Centralized Lubrication unit | |||||

| Motion | Rack and Penion with Gearbox | |||||

| Limit | Electric Limit Switches with Mechanical arrangements | |||||

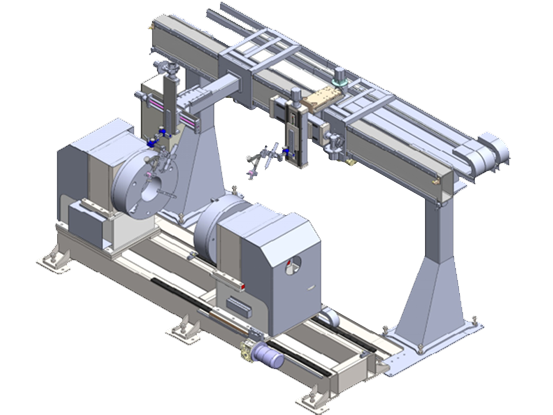

Pipe to Flange Welding Machine

Pipe To Flange Welding Machine has 2 Station i.E Station 1 And Station 2. On Station 1 You Can Weld Tig Type of Welding on Station 2 you can only Weld Saw Welding.

Pipe to Flange has two Chuck (Chuck 1 and Chuck 2) Both can Operate at Cobined Mode and also indivually as Per the Requirement.

Each Station Consists of one avc,Weaver and Rotator. it Consists of two Wireless Remote to Operate.