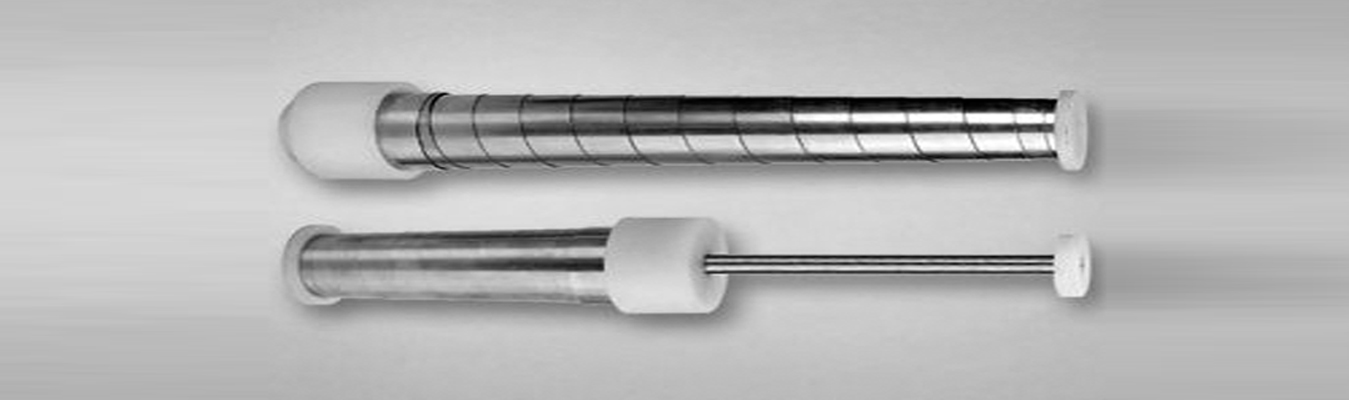

Spiral Spring Covers

The spiral spring is under constant tension! Remove the wires as described below under "Installation" only after the Spiraled spring has been fitted over the shaft!

Safety information:- The spiral spring must be used only together with the part to be protected, i.e. a ballscrew, etc., otherwise it can snap out unexpectedly and cause grievous injury!.

Conditions of use:- Spiral springs operate optimally in oily environments. In environments with fine particles or larger dust accumulations, e.g. from wood processing, bellows must be used instead.

Warranties:- Our warranty for spiral prings extends to material and production defects only. Our warranties do not extend to damage incurred as a result of improper installation, loading, and failure to service or clean, e.g. swarf accumulation. Installation

Care:- Spiral springs must be cleaned at regular intervals. Whenever possible, only W44T Turbo spray. must be used for cleaning and lubricating.Viscous, resinous oils can clog the Spirals and fracture the spring and are therefore unsuitable. The use of unsuitable lubricants renders the warranty void.

Advantages of Spiral Spring Covers

- Keeps the ballscrew safe from any kind of foreign matter such as dust,chips,coolent Etc.

- Very easy install as no provision is required for fixing at each end.Because of spring pressure it keeps contact at both ends

- Material is stainless steelswith surface coating and heat treated ensures long and maintainance free life.

- Very useful in application where Ballscrewis not covered and easy to get damaged.

Some Application Industries are follows

- Wood Working Machinery/Routers Manufactures

- Granite Machinery.

- CNC Plasma & Oxyfuel Cutting Machines.

- Laser Machine Maufactures

- Glass Machinery

- Welding SPMS Machinerys

- Retrofitters of Machining Centers